Our services

We provide a wide range of professional services to meet your needs. We promise to provide every service with a smile, and to your highest level of satisfaction.

Our services

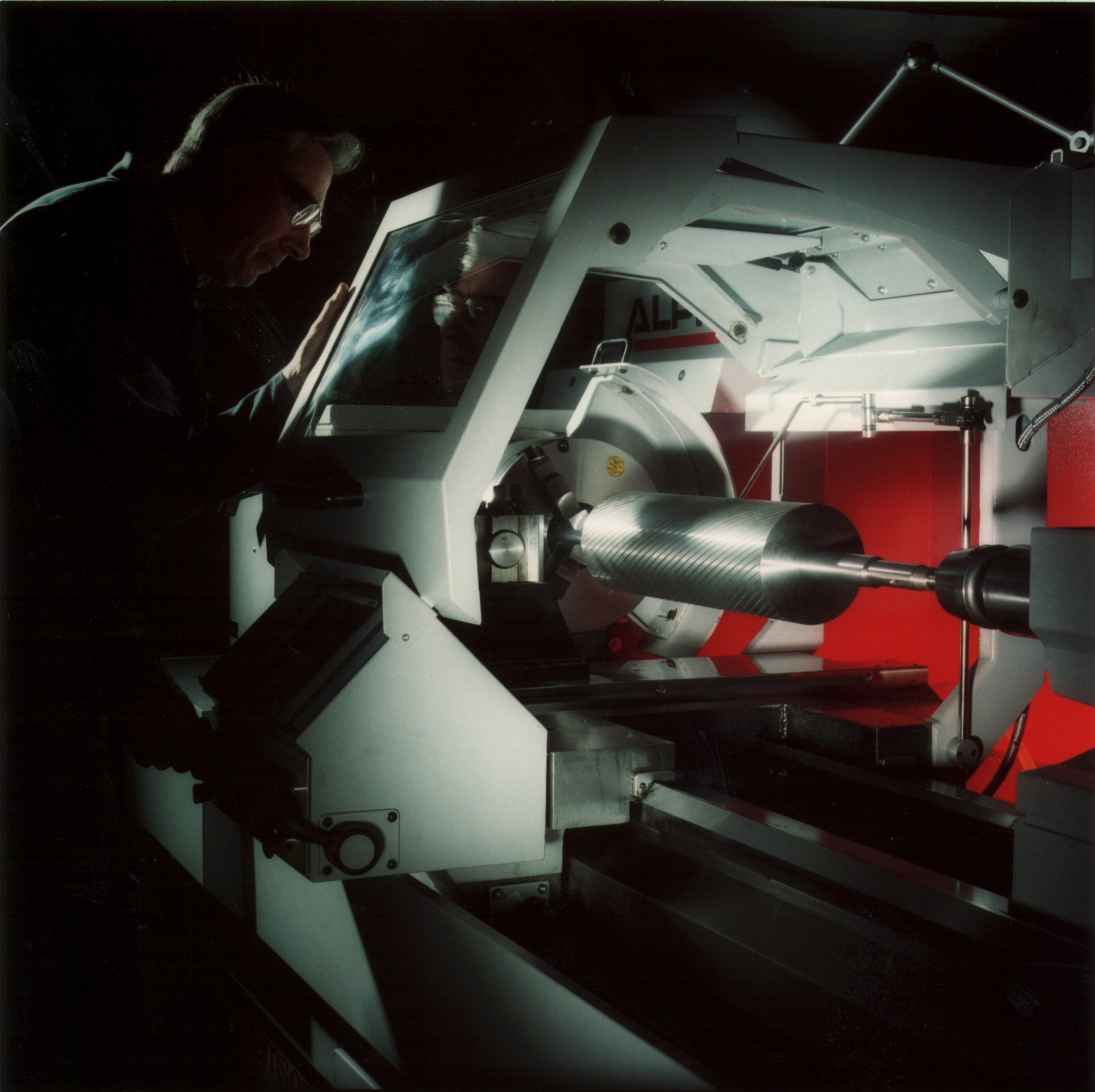

Specialist Engineering

Precision machined components, turned and milled to customer drawings or samples. CNC milling and turning coupled with conventional machine capacity allows us to produce to customer's needs.

Fabrication & Welding

We can deisgn special purpose machinery to customer specifications. Fully fabricated components are machined when necessary to ensure drawing dimension accuracy.

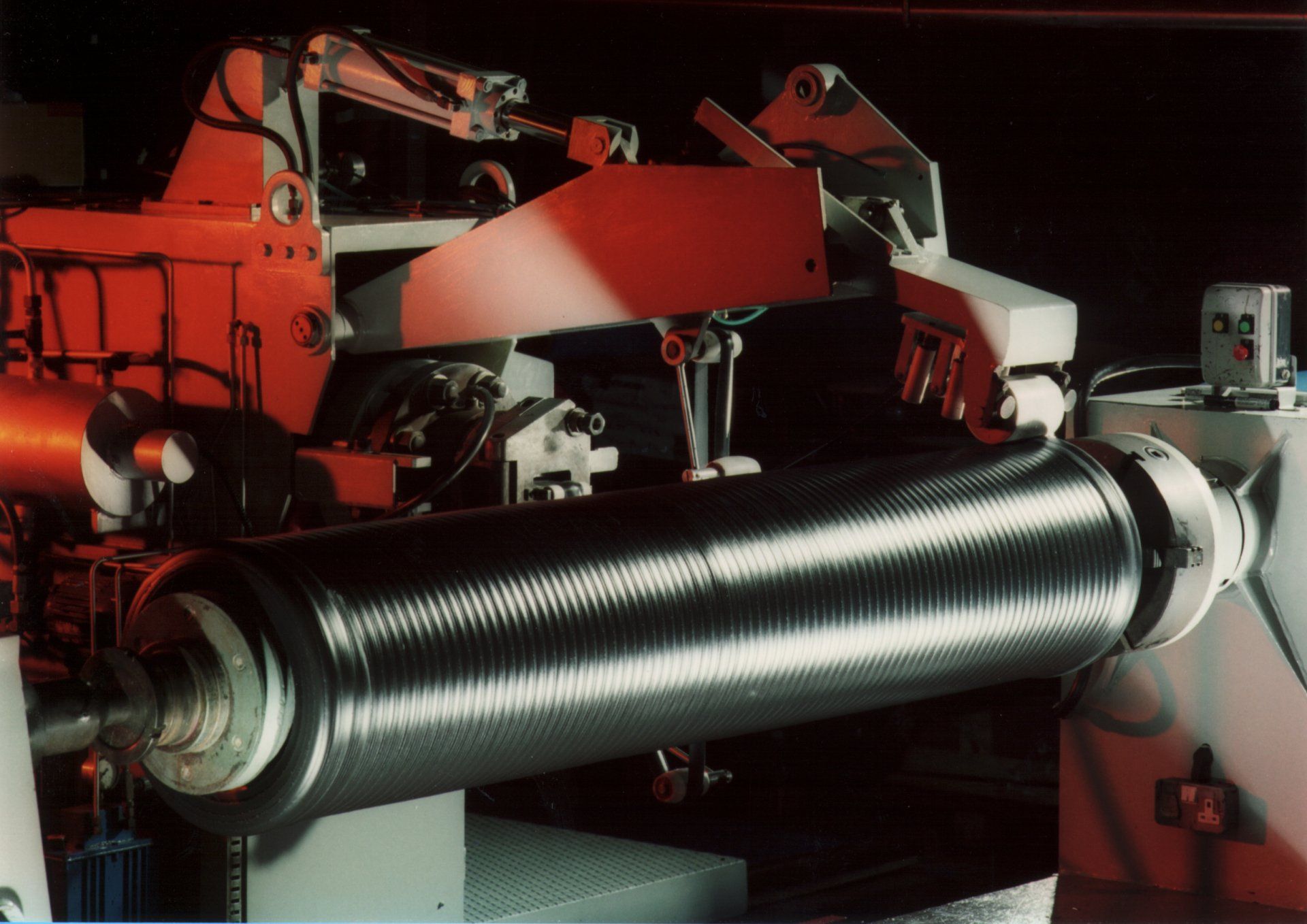

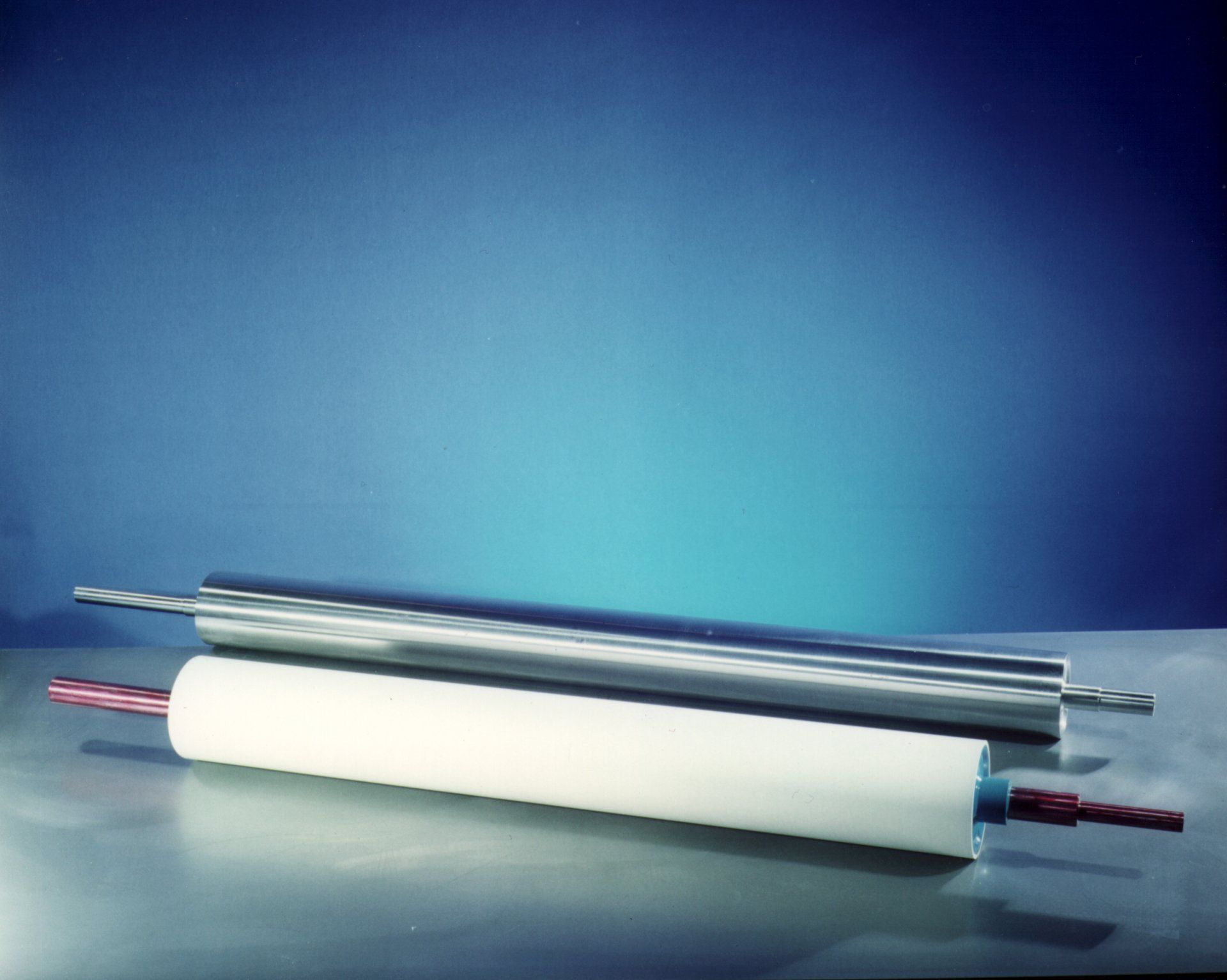

Roll Rubber Covering

Specialised rubber covering and coatings applied to rollers using various compounds. Fife Engineering has established a broad knowledge of roll covering in most industries from specialist high temperature roller covering to super finished embossed rollers.

Fast Response

We supply a fast response to urgent breakdowns to reduce customers downtime.

Customer Specifications

We can design special purpose machinery to customer specifications.

Collection and Delivery

At Fife Engineering, we operate a collection and delivery service for our customers using either our own vehicles or a national carrier.

ISO Certified

Fife Engineering is an ISO 9001:2015 accredited company and employ a 100% inspection policy on all manufactured components.